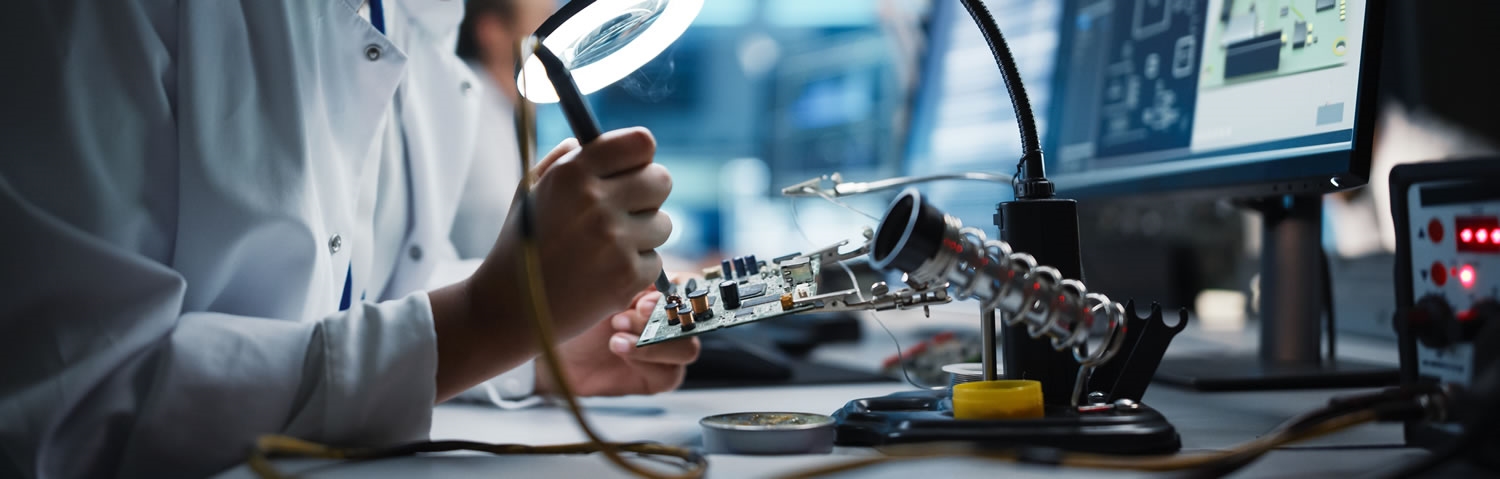

Cleaners & Soldering Tools for PCB Rework & Repair

All over the world, for over 40 years, thousands of service people have counted on Techspray cleaners and Plato soldering tips and tools for their electronic repair needs.

Desoldering braid (wick) is an essential electronic repair tool that allows components to be replaced and excess solder (e.g., bridging) to be removed. Techspray offers desoldering wick that has faster wicking action, and no-clean wick that is the cleanest in the industry, making post-repair cleaning optional.

TraceTech PCB repair system allows any level of technician to quickly perform quality board repairs in-house without the use of expensive equipment or time-consuming and unsightly jumpers.

If cleaning is needed after repairing electronics, Techspray flux removers (defluxers) effectively clean off flux residues and other contaminants from printed circuit boards. Residues from higher, lead-free temperatures are harder to clean. PWR-4™, G3®, E-LINE™ and Precision-V™ flux removers have been proven very effective at removing fluxes baked on at lead-free temperatures.

Plato is one of the largest manufacturers of solder tips in the world, producing tips to fit the most popular solder stations. The long life and fast heat recovery of a Plato solder tip provide the most efficient electronic repair operation possible.

Elect Repair

ESD Attributes

Environmental & Safety

Applied Filters

FAQ's

Whether or not conformal coating is required depends on the environment the electronic device will operate in, the reliability requirement of the device, and the cost of failure, whether in dollars or human lives. Typical consumer devices are generally not coated because cost is one of the top driving factors, and a coating step certainly adds to that. Devices operating in harsh environments may require coating, and the type of stresses and contamination will point to the best option, whether that is acrylic resin (AR), silicone resin (SR), urethane resin (UR), or some other type of protection. Aviation, aerospace, and medical devices often require coating because of the mission critical nature of these applications.

1. Flux is being used so liberally that it all isn’t being heated along with the solder.

or

2. The non-ionic residue can impede with the function of the devise either short-term or long-term.