Safe, Effective Cleaners & Cleaning Tools to Keep Your Facility Running

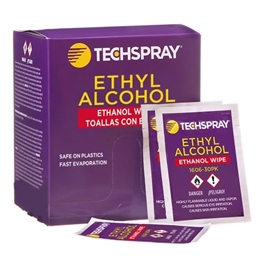

Keeping a manufacturing facility operational is a day-to-day challenge, requiring the best tools and supplies. Techspray offers brushes, wipes and cleaning chemicals that are aggressive enough for efficient plant maintenance.

Techspray offers a variety of solvents, industrial degreasers, and water-based cleaners that allows you to match the right products for your cleaning needs. Maintenance cleaners clean oil and contaminants from metal parts, printed circuit boards, barcode instruments, switch boxes, gear boxes, and engines.

Our contact cleaners remove oxidation, oil, and other contaminants from contacts, metal switches, motors, relays, generators, edge connectors, buss bars, circuit breakers, scales, and sensors.

Techspray Duster blows away dust, microscopic contaminants, lint, metallic oxide deposits and other soils that can damage sensitive electronics. When these contaminants get in the way of vents or fans within the device, they build-up which leads to overheating and/or shortages.

Soil Type / Application

Plastic Sensitivity(Choose One)

Environmental & Safety

-

Low GWP

Low GWP

-

Low VOC - CARB

Low VOC - CARB

-

Low VOC - EPA

Low VOC - EPA

-

Low VOC - EPA NESHAP Compliant

Low VOC - EPA NESHAP Compliant

-

Low VOC - SCAQMD

Low VOC - SCAQMD

-

PFAS-free

PFAS-free

-

VOC-free

VOC-free

Cleaning Method

Applied Filters

FAQ's

Every organization using hazardous chemicals within their facility has the responsibility to equip their facility and personnel to maintain exposure levels below the TLV. Personal monitoring badges can be used to measure exposure of a specific material. Then, depending on the threshold limit and the application, exposure can be controlled with PPE like masks, face shields, respirators, and even coveralls. If they don’t reduce exposure below the recommended limit, you will need to consider a special ventilation hood or even containment booth. As you can see, as the exposure limit gets down to a certain level, the equipment required to safely use the solvent can get impractical. At that point, your best option is to consider a safer alternative.

A degreaser is intended to clean a surface, so remove contamination. A degreaser is designed specifically to remove oils, greases, and lubricants. Sanitizers are intended to kill various pathogenic agents, like bacteria and viruses. There are materials that can do both, like 70% isopropyl alcohol (per CDC guidelines for hard surface disinfecting), but don’t assume all degreasers will kill pathogens.

The ingredients of a degreaser can vary wildly depending on the product. Generally speaking, they fall into 2 camps: 1) solvent cleaners – this includes alcohols (like isopropyl alcohol, or ethyl alcohol), hydrocarbons (like heptane and mineral spirits), ketones (like acetone and xylene), and more exotic compounds and blends. 2) water-based cleaners – these include ingredients dissolved or blended with water. Which is best for your application depends on the type of soil and various requirements like performance, evaporation rate, toxicity limits, and environmental regulations.