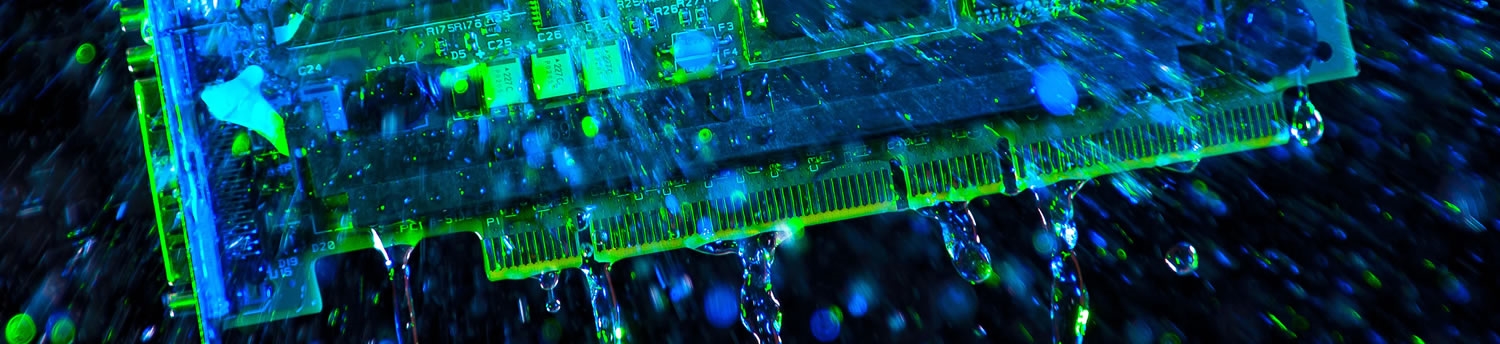

An ultrasonic cleaning process utilizes equipment to transmit ultrasound waves, generally between 20-40 kHZ. The transducers send those sound waves through the liquid cleaner, which acts as a transfer medium from the transducers to the parts. At very high frequency, the waves may pass over the surface of the parts, creating agitation through a process called acoustic streaming. As the frequency is reduced, it creates cavitation within the liquid. These voids quickly collapse, generating heat and shock waves, which creates agitation in the cleaning process.

Subscribe

Stay up-to-date on Techspray news, products, videos & more.

Related Categories

You did not finish submitting your information to request a sample