Increase Thermal Dissipation and Improve Interface with Mechanical Heat Sink

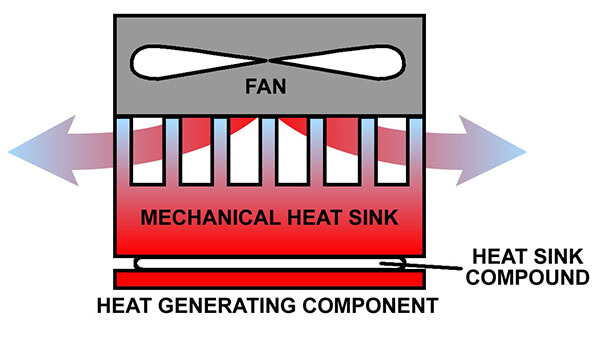

Heat sink compound, which is also called thermal grease, thermal paste, thermal compound, CPU grease, heat paste, heat sink paste, and thermal interface material, is designed to efficiently transfer heat away from a heat-generating component. For electrical applications, heat sink compound is used to thermally bond a component with a mechanical heat sink. The compound fills the gap between the CPU (central processing unit) or other heat generating components.

In addition, heat sink paste is used with thermocouple wells, thermistors, and calrods, or wherever efficient cooling is required. Although heat sink paste does not have the thermal conductivity of metals like copper and silver, the improvement over the air will increase thermal responsiveness.

Environmental & Safety

Applied Filters

FAQ's

When a CPU or GPU operates, it generates heat due to the electrical resistance in the transistors and other components. To prevent the device from overheating, a heat sink is used to dissipate this heat away from the chip. However, there are microscopic imperfections on both the chip's surface and the heat sink's base that can create tiny air gaps between them. Air is a poor conductor of heat, so these gaps can reduce the efficiency of heat transfer.

Here's how thermal paste works to overcome this problem:

- Filling in imperfections: Thermal paste is a viscous material with high thermal conductivity. When applied, it fills in the microscopic imperfections on the surfaces of the CPU/GPU and the heat sink. This ensures that there is maximum contact between the two surfaces, minimizing the number of air gaps.

- Enhancing thermal conductivity: The thermal paste is designed to have a much higher thermal conductivity than air. By creating a continuous layer of thermal paste between the chip and the heat sink, it allows heat to flow more easily from the CPU/GPU to the heat sink.

- Eliminating air pockets: Air pockets can act as insulators, hindering the heat transfer process. The thermal paste helps to eliminate these pockets, promoting a more efficient transfer of heat.

- Compensation for surface irregularities: Even if the surfaces of the CPU/GPU and the heat sink appear smooth, they often have microscopic irregularities. Thermal paste, being a malleable material, can conform to these irregularities, further improving the contact area and heat transfer efficiency.

For more information, check out "How Heat Sink Compound Keeps Electronics Cool".

Note: Before starting, make sure to clean the surfaces of the CPU/GPU and heat sink with a lint-free cloth and isopropyl alcohol to remove any existing thermal paste or debris.

Step 1: Choose the right amount of thermal paste. Generally, a small pea-sized amount or a thin line along the center of the CPU/GPU is sufficient. Using too much can cause excessive spreading and lead to uneven heat distribution.

Step 2: For most CPUs and GPUs, it's best to apply the thermal paste directly onto the center of the CPU/GPU. If your CPU/GPU has an integrated heat spreader (IHS), apply the paste on top of it.

Step 3: If you have a CPU without an IHS, you can apply the thermal paste directly to the center of the CPU die. However, this method requires more precision and is generally recommended for experienced users.

Step 4: Once you've applied the thermal paste, carefully place the heat sink on top of the CPU/GPU. Make sure the heat sink is aligned with the CPU/GPU, and then gently press it down.

Step 5: Secure the heat sink in place using the appropriate mounting mechanism for your CPU/GPU socket. This could involve screws, brackets, or other fasteners, depending on your system.

Step 6: Avoid twisting or sliding the heat sink after it's in contact with the thermal paste. Doing so can create air pockets and reduce the effectiveness of the thermal transfer.

Step 7: Double-check to ensure that the heat sink is firmly and evenly seated on the CPU/GPU. If it's not making proper contact, you might need to reapply the thermal paste and try again.

Step 8: Reassemble the rest of your computer components, ensuring everything is properly connected and secured.

Step 9: Power on your system and monitor the temperatures to ensure that the thermal paste is doing its job correctly.

Remember, when applying thermal paste, less is often more. The goal is to fill any gaps and create a thin, even layer for optimal heat transfer. With proper application, you can ensure that your CPU/GPU stays cool and performs optimally.

For more information, check out "How Heat Sink Compound Keeps Electronics Cool".

We design thermal pastes with materials that have low electrical conductivity to prevent any possibility of short circuits or electrical interference when applied between electronic components. This is essential because these compounds are often used in areas where electronic components are densely packed together.