Mask Open Vias for Wave Soldering & Conformal Coating Keep-out Areas

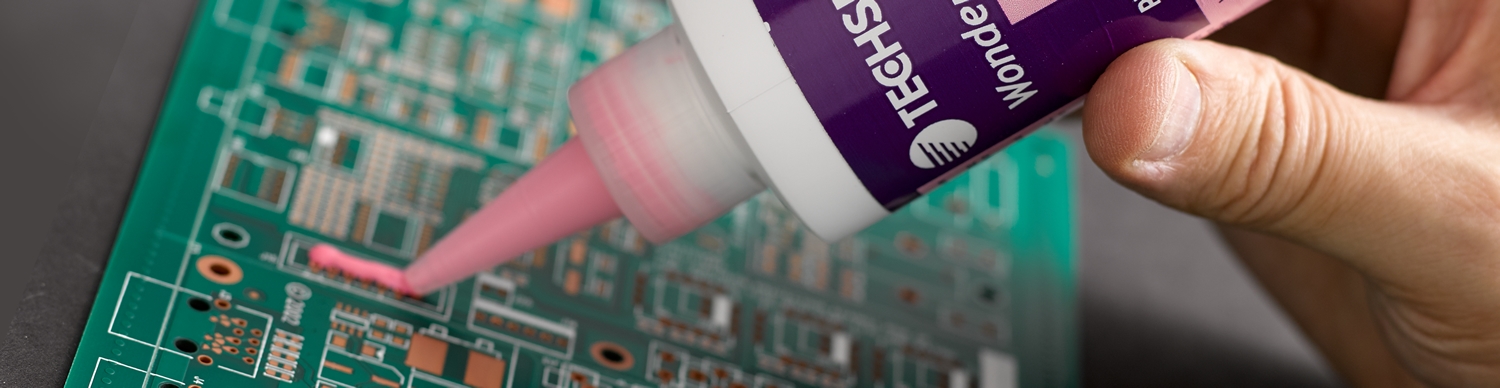

Techspray’s WonderMASK is the industry leading temporary solder mask brand because of quality and versatility. Depending on the product, mask can be peeled off manually or washed off in a batch or inline system.

WonderMASK has several useful applications in PCB assembly:

Thru-hole masking – Prevent soldering open holes in a wave soldering process by covering with WonderMASK. All of the masks listed below are well suited for this application.

Conformal coating masking – In a conformal coating dipping or spraying process, WonderMASK can be used to cover connectors and other components and areas that should not be coated. WonderMASK P and PX are recommended.

Temporary component adhesive – WonderMASK can be used to tack down components on double-sided PCBs.

All Techspray WonderMASK products have the following advantages:

- Withstands lead-free soldering temperatures up to 640°F (343°C) in wave soldering process

- RoHS compliant

Removal Method

Dispensing Methods

Sensitive Metal

Flammability

Environmental & Safety

Applied Filters

FAQ's

For more in depth information, check out "How To Use Spot Mask for Wave Soldering & Conformal Coating".