Safe, Effective Vapor Degreaser Solvents

Techspray has an array of vapor degreasing cleaners that are engineered to be less toxic than many other solvents, yet powerful enough for the most difficult soils.

Vapor degreasing is a cleaning process that involves rinsing and cleaning parts in ultra-pure vapor. The process doesn’t require any water or scrubbing and is used to safely clean various materials like plastic, glass, metal, gold, and ceramic.

Vapor degreasing can be found in any industry where precision cleaning is critical. It is common in the automotive, aviation and aerospace fields, and in medical device, jewelry, and electronic assembly manufacturing.

Precision-V vapor degreasing solvents are ideal replacements for cleaners containing Freon, HFC-141b, and AK225. Exposure to Precision-V solvents is less hazardous than many other solvents: TCE (trichloroethylene, CAS #79-01-6), nPB (n-propyl bromide, CAS #106-94-5), and perc (perchloroethylene, CAS #127-18-4).

For the closest (and safest) cost and performance match to n-propyl bromide, nothing beats PWR-4 Maintenance Cleaner and PWR-4 Flux Remover.

Click here for the latest information on the EPA’s designation of n-propyl bromide as an “unacceptable risk”. Check out the in-depth discussion on the topic in our webinar “Replacing N-Propyl Bromide (NPB): What You Don’t Know CAN Hurt You”.

Not sure which product is right for your application? Check out our Vapor Degreaser Product Selection Guide or our technical article “Vapor Degreasing: The Quick Guide”.

Looking for 3M Novec Replacements?

Check out our Novec replacements page.

Soil Type / Application

Plastic Sensitivity(Choose One)

Environmental & Safety

-

Low GWP

Low GWP

-

Low VOC - CARB

Low VOC - CARB

-

Low VOC - EPA

Low VOC - EPA

-

Low VOC - EPA NESHAP Compliant

Low VOC - EPA NESHAP Compliant

-

Low VOC - SCAQMD

Low VOC - SCAQMD

-

PFAS-free

PFAS-free

-

VOC-free

VOC-free

Flux Type

Applied Filters

FAQ's

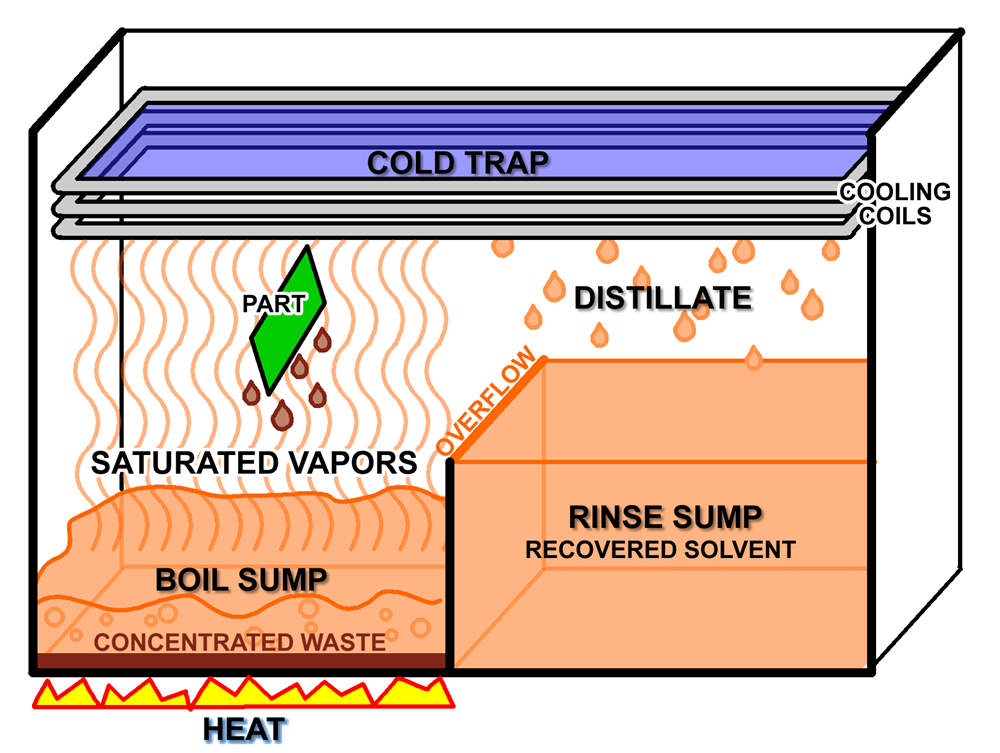

The vapor degreasing process typically takes place in a closed chamber or tank with two distinct sections. The lower section contains the solvent, while the upper section holds the parts to be cleaned. The solvent is heated to its boiling point, creating vapor that rises and comes into contact with the soiled parts. As the vapor condenses on the colder surfaces of the components, it liquefies and effectively dissolves the contaminants. Gravity then causes the dissolved contaminants to drain off the parts and settle in the bottom of the tank.

The key advantages of vapor degreasing are its ability to remove stubborn contaminants thoroughly and quickly, its compatibility with various materials, and its relatively low energy consumption compared to other cleaning methods. It is also a closed-loop process, so solvent is reclaims and used over-and-over. Additionally, the process can be automated for large-scale industrial applications, leading to increased productivity and consistency in the cleaning results.

For more information on vapor degreasing, check out "Vapor Degreasing: The Quick Guide".

Here are some safety considerations for vapor degreasing:

- Solvent Choice: The safety of vapor degreasing largely depends on the solvent used. Some solvents, such as chlorinated solvents like trichloroethylene (TCE) and perchloroethylene (perc), and bromiated solvent like n-propyl bromide (nPB) have been associated with health and environmental hazards. These solvents can pose serious risks if not handled properly, and their use is being phased out or regulated in many regions. We offer many alternatives with much lower toxicity, and we do not offer TCE, perc, and nPB because of the health concerns.

- Ventilation: Adequate ventilation is crucial to prevent the buildup of potentially harmful solvent vapors in the workspace. Proper ventilation helps maintain air quality and reduces the risk of exposure for workers.

- Personal Protective Equipment (PPE): Employees working with vapor degreasing equipment should wear appropriate personal protective equipment, such as gloves, goggles, and respirators, to protect against potential contact with solvents or vapor inhalation.

- Environmental Impact: Adequate disposal methods and compliance with environmental regulations are necessary to minimize the impact on the environment.

- Training and Safety Measures: Workers involved in vapor degreasing should receive proper training on handling solvents, operating equipment, and understanding safety protocols to minimize risks.

Every organization using hazardous chemicals within their facility has the responsibility to equip their facility and personnel to maintain exposure levels below the TLV. Personal monitoring badges can be used to measure exposure of a specific material. Then, depending on the threshold limit and the application, exposure can be controlled with PPE like masks, face shields, respirators, and even coveralls. If they don’t reduce exposure below the recommended limit, you will need to consider a special ventilation hood or even containment booth. As you can see, as the exposure limit gets down to a certain level, the equipment required to safely use the solvent can get impractical. At that point, your best option is to consider a safer alternative.