The follow are factor to consider when trying to avoid breakage:

- Curing – Partially cured mask will have more of a tendency to break or leave residue.

- Temperature and duration in extreme heat – Mask is designed for wave soldering, which is about a second of exposure to molten solder temperatures (generally 550°-650°F). If the mask is sent through a reflow oven the duration is much longer, which can lead to more mask brittleness. If the mask is exposed to high-temperature solder (e.g. silver), it can also lead to more brittleness.

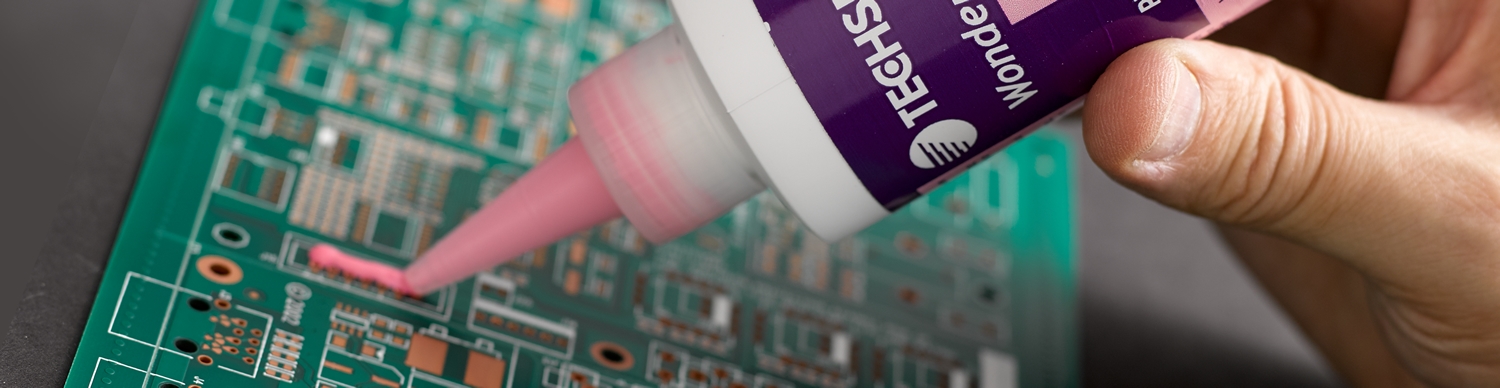

- Application method – When hand applying, we recommend holding the bottle at about a 60° angle, rather than upright at 90°. That tends to apply the material as a thick blanket over the areas to be masked. When the bottle is held at 90°, the mask is generally applied thinner, and is forced through holes and around components. Those thin areas are more likely to become brittle and stay behind, and mask pushed into holes and around components is harder to remove, so more likely to break.