Supply chain shortages resulting from the reopening of businesses and lifting of COVID-19, among a myriad of other factors, have impacted the manufacture of medical implantable devices and surgical instrumentation. 3M Novec and Chemours Vertrel-based solvents, which are commonly used in the vapor degreasing of machined parts, have been difficult to acquire and prices have increased dramatically.

This is challenging enough for commodity products, but can be catastrophic to the manufacture of medical devices and implantable parts.

According to a survey by the American Chemistry Council (ACC), there have been supply chain disruptions and transportation constraints impacting the availability of chemical products all over the US. 94% of chemical manufacturers reported shipping delays and shortages of raw materials and 93% reported increased transportation costs. Additional costs were estimated to be between $100 to $200 million [1], leading to drastic price increases down the line.

3M’s Belgium-based chemical processing plant has been shut down (as of May ’22) due to the stringent discharge standards of PFAS.[2] The loss of this production capacity has led to global shortages of Novec-branded solvents.

Currently, companies are scrambling to identify and qualify replacements for common solvents used for vapor degreasing: 3M Novec 71DA, 71IPA, 71DE, 72DE, and Chemours Vertrel-based solvents.

What is Vapor Degreasing?

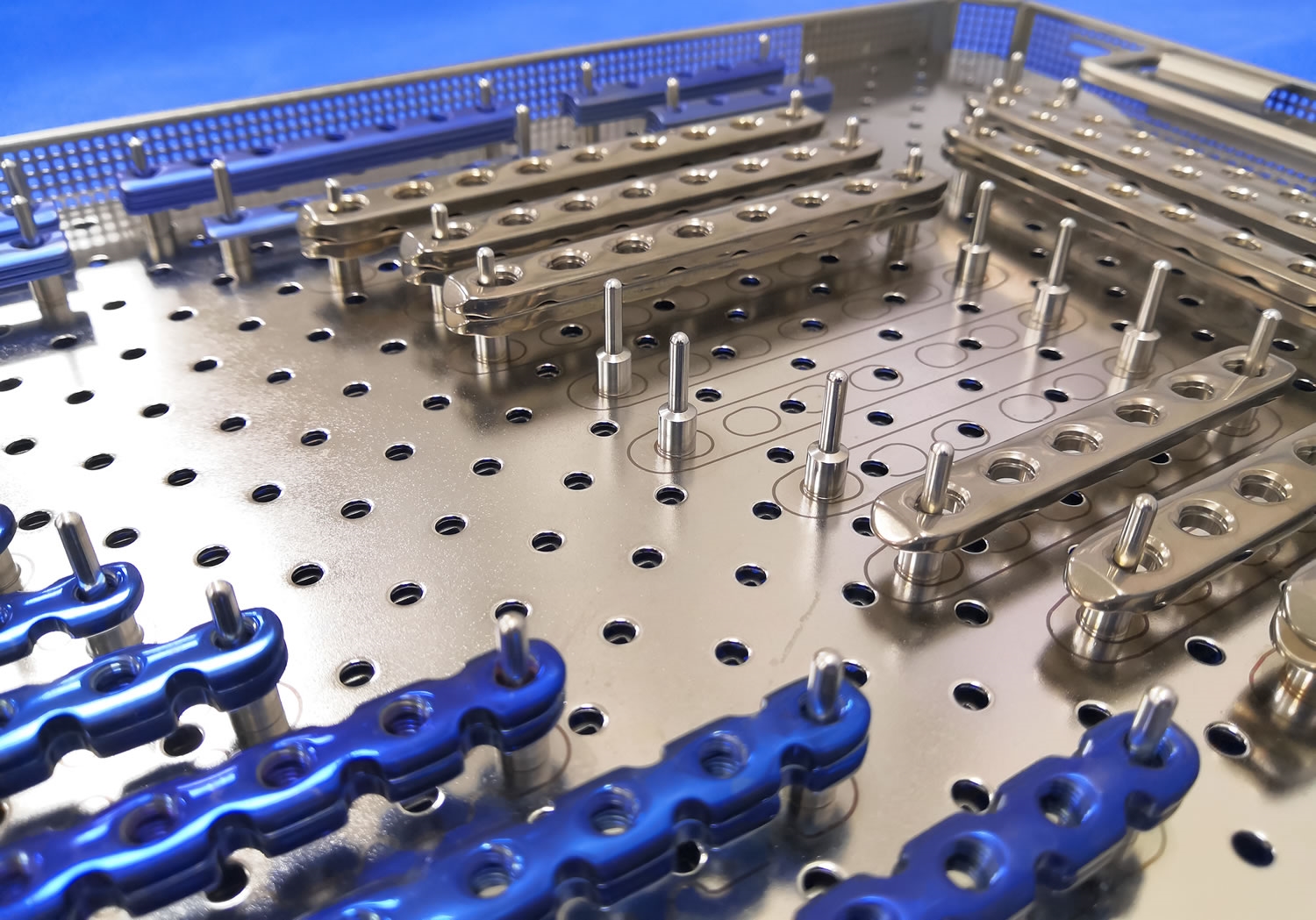

Vapor degreasing cleaning equipment use solvent vapors to cleanse and remove contaminants from parts. This process is used to clean various materials during the manufacturing process such as plastic, metal, and ceramic. In almost any industry where precision cleaning is paramount to the manufactured parts vapor degreasing can be found. It is commonly used for cleaning machined parts in implantable devices like screws, plates, and replacement joints, and in surgical instrumentation.

Techspray has been supplying critical application vapor degreaser solvents for decades, including popular HCFC-141b and AK225-based products. More recently, Techspray has introduced PWR-4 vapor degreaser solvents to fill the need for critical cleaning materials that are both effective and safer than many of the alternatives, like n-propyl bromide.

Top Criteria to Consider for Replacement Solvents

To find the best replacement chemistry for your operation, you should first identify and prioritize the most important characteristics:

- Cleaning performance – Performance is dependent on the soil and process, so it is difficult to know how a replacement performs until it is tested with a design of experiment (DOE) as close to your process as possible.

- Sensitive materials – If your products contain polycarbonates, rubber gaskets, and chemically sensitive components, you’ll need to select a solvent with compatibility in mind. This is less of an issue for metal cleaning like titanium machined parts.

- Azeotropic –To work in a vapor degreaser, all of the constituents of a solvent blend need to boil at the same temperature, so that as the solvent is vaporized and reconstituted hundreds of times the properties don’t change. In true azeotrope solvents, the combination of solvents boil together, so won’t drift even when run through a reclamation process. Terms like “near azeotrope” or “azeotrope like” are used when under normal use, the solvent will act like an azeotrope.

- Flammability – Vapor degreaser solvents need to be nonflammable as defined by the Global Harmonized System (GHS). For oxygen system cleaning, the requirement is either a single nonflammable component or true azeotrope to ensure that the performance properties will remain constant.

- Regulatory compliance – Volatile organic compounds (VOC) and global warming potential (GWP) could be an issue depending on federal and local requirements.

- Toxicity – Solvents like n-propyl bromide (nPB), trichloroethylene (TCE), and perchloroethylene (perc) were common in the past, but have fallen out of favor because of health concerns like lung cancer, renal failure, impact on cognitive functioning, and reproductive effects. If considering cleaners containing one of these solvents, make sure to factor in the cost of required ventilation and PPE to maintain a safe working environment.

Tips for Evaluating Replacement Solvents

Engineers leading the search for replacement solvents will often try to build ingredient lists for comparison. One difficulty in building comparative lists is you are often dealing with proprietary formulas. Chemical suppliers do not generally pass out their formulas freely without non-disclosure agreements (NDAs) in place. In addition, it is unlikely you will find an exact match. You will find significant differences and then will need to figure out the relevance to your key criteria.

Before you can develop a testing protocol, establish what is considered clean. Implantable devices could require testing the final device for bacterial or fungal contamination.

Document your current process so for initial qualification, the process can be replicated, and then only changed as needed. Important process parameters include:

- Time submerged in boil sump.

- Whether ultrasonics are included in the sump.

- Time in vapor phase.

- If repeated, how many times?

- Is a spray wand being used?

- Any offline cleaning?

Techspray PWR-4 Vapor Degreaser Solvents

Companies across industries are turning to Techspray as a replacement supplier for expensive and difficult to find 3M Novec and Chemours Vertrel solvents. Our PWR-4 High-Performance Vapor Degreaser Solvents are a safer and more cost-effective alternative. They remove cutting fluids, tap oils, and particulates from machined metal, ceramic, and plastic parts.

Techspray PWR-4 solvents have been tested and qualified for use in all the most popular vapor degreaser equipment including Baron Blakeslee, Branson, CREST, and more.

Techspray PWR-4 advantages over Novec and Vertrel solvents:

- Available for immediate shipment

- Lower cost

- Stronger cleaning performance

- Effective on a wide variety of soils

- Safe and noncorrosive on common implantable materials like titanium, silicone and ceramics

- Low toxicity – ideal replacement for nPB

Techspray Qualifications Lab

Techspray lab offers a state-of-the-art cleaning, coating and analytical services to help customers qualify new products and optimize their processes. Cleaning equipment includes inline, batch, ultrasonic, and vapor degreasing systems. This equipment allows us to better duplicate your production environment for process optimization and troubleshooting.

Contact Techspray at 678-819-1408 or info@itwcce.com for free qualification testing. We are available to help qualify new cleaning processes, evaluate current processes, or troubleshoot contamination issues.

Resources

[1] Cision PR Newswire, American Chemistry Council, 10 Jan. 2022, “New Survey Finds Persistent Supply Chain Problems Deeply Impacted Chemical Manufacturers”. https://www.prnewswire.com/news-releases/new-survey-finds-persistent-supply-chain-problems-deeply-impacted-chemical-manufacturers-301457352.html

[2] The Brussels Times, by Lauren Walker, 8 March 2022, “Belgium rejects 3M appeal and tightens regulations on hazardous chemicals”. https://www.brusselstimes.com/209902/belgium-rejects-3m-appeal-further-tightens-standards-regarding-hazardous-pfas

https://www.techspray.com/epa-considers-n-propyl-bromide-npb-an-unacceptable-risk-for-degreasing