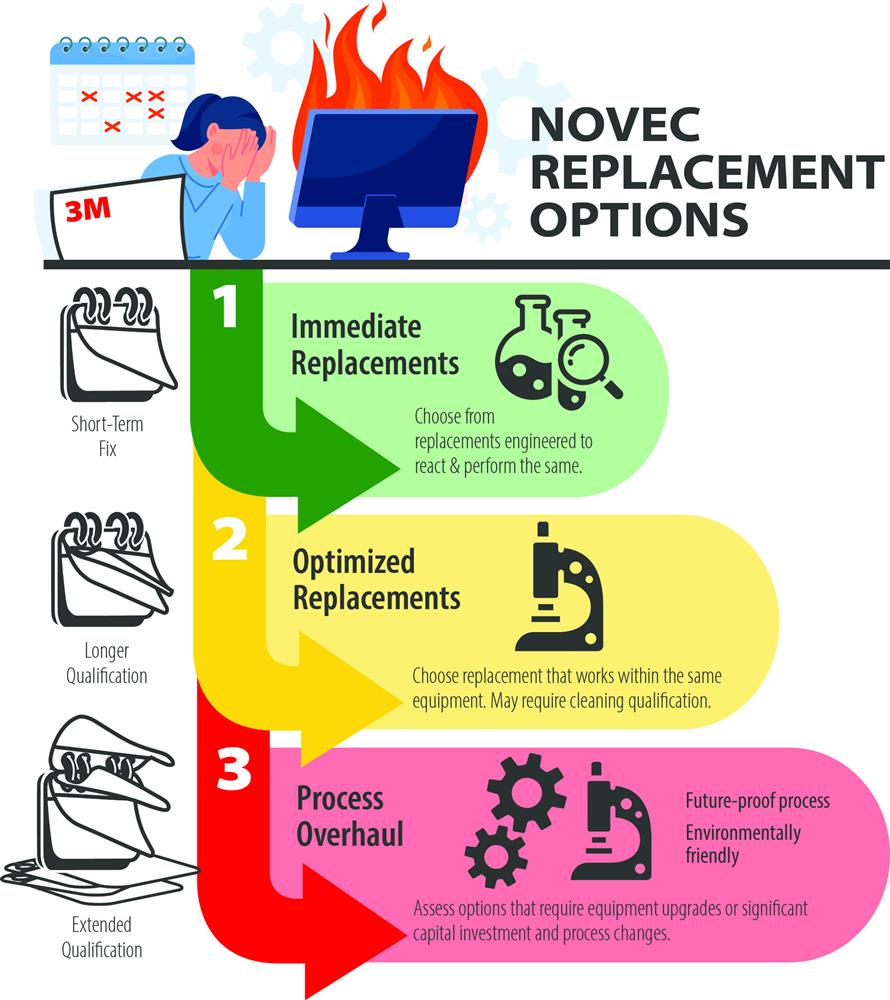

On December 20, 2022, 3M announced their plans to phase-out their Novec PFAS-based product lines by the end of 2025. At Techspray, our focus is on high-precision cleaning chemistries, which include chemical replacements for NOVEC and proprietary formulas. Below is an infographic on the available options for critical cleaning operations, like those in aerospace or medical equipment manufacturing. Click on the options for a more detailed explanation of each.

Immediate Replacments for 3M Novec Solvents

For companies reacting to the unreliable availability of Novec solvents, Techspray offers a line of replacements that have been engineered to react and perform the same as Novec solvents. Cleaning qualification testing is optional. COC’s are available to ensure your strict quality standards are maintained.

| 3M Novec # | Techspray Replacements |

| 7100 | Precision-V 3710 |

| 71DA | Precision-V 371DA |

| 71DE | Precision-V 371DE |

| 71IPA | Precision-V 371IPA |

| 7200 | Precision-V 3720 |

| 72DA | Precision-V 372DA |

| 72DE | Precision-V 372DE |

| 7300 | Precision-V 3730 |

| 73DE | Precision-V 373DE |

Optimized Replacements for 3M Novec Solvents

Choose one of Techspray’s replacements, under the product brands PWR-4 and Precision-V, for improved performance and cost. Custom formulations are available to meet specification requirements (e.g. low GWP, PFAS-free).

- PWR-4 solvents are designed to replace nPB, TCE and Perc, matching and surpassing cleaning performance without the safety concerns.

- Precision-V vapor degreaser solvents are ideal replacements for 3M Novec solvents and AK-225 based cleaners, which were phased out due to the ozone depletion restrictions of the Montreal Protocol.

| 3M Novec # | Techspray Drop-in Replacement |

| 7100 | Precision-V Solvent 3810 |

| 71DE | PWR-4 Solvent 3410 PWR-4 Industrial Maint. Cleaner PWR-4 Flux Remover |

| 7200 | Precision-V Solvent 3810 |

| 72DA | PWR-4 Solvent 3410 |

| 72DE | PWR-4 Solvent 3410 PWR-4 Industrial Maint. Cleaner PWR-4 Flux Remover |

| 7300 | Precision-V Solvent 3810 |

| 73DE | PWR-4 Solvent 3410 PWR-4 Industrial Maint. Cleaner PWR-4 Flux Remover |

Future-Proofing Your Cleaning Process

3M's abrupt decision to exit their Novec solvent line has put a spotlight on the topic of "forever" chemicals, otherwise known as PFAS. Polyfluoroalkyl (and perfluoroalkyl) Substances (PFAS) are a class of chemicals used in a wide variety of applications, including high precision cleaning for industries like aerospace and medical device manufacturing.

Environmental agencies, including the US Environmental Protection Agency (EPA), have been focused on PFAS because they tend to break down very slowly, and accumulate in the environment, animals and even people over time.[“Our Current Understanding of the Human Health and Environmental Risks of PFAS”, EPA, https://www.epa.gov/pfas/our-current-understanding-human-health-and-environmental-risks-pfas (accessed 1/4/23).] That’s why they have been nicknamed “forever chemicals” in popular media.

PFAS-based solvents came into common use for vapor degreasing because they excel at quenching the flammability of hydrocarbons and alcohols, increasing cleaning performance. They are also much less toxic than n-propyl bromide (nPB), a lower cost, high performing solvent considered to have a number of negative health effects, including carcinogenicity. In short, PFAS have made critical cleaning safer. Special considerations are needed when trying to design a PFAS-free cleaning system. Because PFAS-free alternatives are either flammable, water-based, or boil at very low temperatures, phasing out PFAS will necessitate an overhaul of your cleaning process.

For example, flammable solvents cannot be used in standard vapor degreasing equipment. Special pressurized, explosion-proof systems need to be used. Water-based cleaners require a very different cleaning system like spray-in-air batch or inline cleaning systems. These requirements increase the design and qualfication time needed for the change.

Let Techspray Help You Through Your Transition

Techspray has a large variety of solvents intended for vapor degreasing under the brand names PWR-4™ and Precision-V™. For replacing 3M Novec solvents, we have some direct chemical crosses and options that fit the same criteria, but at a higher cleaning performance.

These products are engineered to be less toxic than many other solvents commonly used in vapor-degreasers: e.g., TCE (Trichloroethylene, CAS #79-01-6), nPB (n-Propyl Bromide, CAS #106-94-5), and Perc (Perchloroethylene, CAS #127-18-4).

Techspray’s TechLab offers state-of-the-art cleaning, coating and analytical services to help customers qualify new products and optimize their processes. Cleaning equipment includes inline, batch, ultrasonic, and vapor degreasing systems. This equipment allows us to better duplicate your production environment for process optimization and troubleshooting.

Contact Techspray at 678-819-1408 or info@itwcce.com for free TechLab qualification testing. We are available to help qualify new cleaning processes, evaluate current processes, or troubleshoot contamination issues.