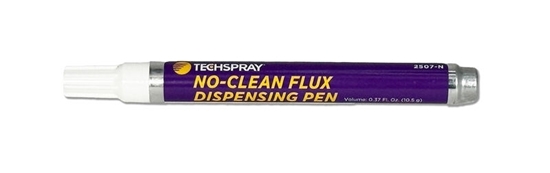

TraceTech No-Clean Flux Pen

No-clean flux applicator pen for PCB rework and repair

FAQ's

When should I clean off no-clean flux when soldering?

If it is not fully activated (brought up to solder temperature), you should not leave any ionic residue behind. You might have to clean if...

1. Flux is being used so liberally that it all isn’t being heated along with the solder.

or

2. The non-ionic residue can impede with the function of the devise either short-term or long-term.

1. Flux is being used so liberally that it all isn’t being heated along with the solder.

or

2. The non-ionic residue can impede with the function of the devise either short-term or long-term.

What flux should I use when replacing PCB components?

TraceTech No-clean Flux Pen is formulated to perform at the elevated temperatures of lead-free soldering but is also effective for tin-lead soldering as well. It's designed with a low surface tension to prevent bridging. Post-soldering cleaning is optional because the light residue left after soldering is barely noticeable is non-corrosive and halide free. Flux pens are an excellent way to dispense flux for benchtop soldering. You just hold the pen vertically and briefly depress the tip to start the liquid flow. This will saturate the tip of the pen with flux. Draw flux on the area to be soldered. Gently press the tip again when more flux is needed to keep the tip damp with flux.

Can I add my own flux to solder wick?

In a production or repair environment where the flux is specified and can’t be changed, or when an aqueous flux is needed, you can add your own flux to this type of braid. Unfluxed wick will not remove solder unless flux is added. TraceTech No-Clean Flux Pen is formulated to perform at the elevated temperatures of lead-free soldering but is also effective for tin-lead soldering as well. It's designed with a low surface tension to prevent bridging. Post-soldering cleaning is optional because the light residue left after soldering is barely noticeable is non-corrosive and halide free. This is a good choice for tin-lead soldering where cleaning is to be avoided.

You did not finish submitting your information to request a sample